https://cksupply.com/wp-content/uploads/2023/06/2019-coronavirus.png-1.jpeg

600

1200

Nate Riggins

/wp-content/uploads/2023/04/CK-Supply-White-Logo.svg

Nate Riggins2020-04-24 12:39:122024-07-26 11:57:58Coronavirus Talk

https://cksupply.com/wp-content/uploads/2023/06/2019-coronavirus.png-1.jpeg

600

1200

Nate Riggins

/wp-content/uploads/2023/04/CK-Supply-White-Logo.svg

Nate Riggins2020-04-24 12:39:122024-07-26 11:57:58Coronavirus Talk

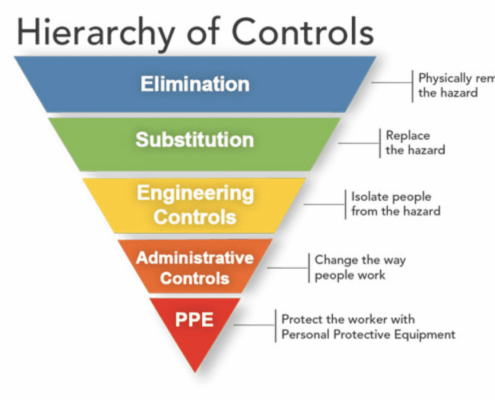

What first comes to mind when you think safety in the workplace? The most common response I get is PPE, or personal protective equipment. The issue with this is that PPE is the acceptance of a known hazard. If PPE is required to perform a job function, you have accepted the fact that there is a level of risk present to require it. So, knowing this, what is the most effective way to control a hazard? The answer is eliminating the issue entirely. With technology being utilized in almost everything we do – eliminating a hazard completely isn’t unrealistic in most cases. For instance, in the gas and welding industry, robotic automated welders are a great way to remove a typical high-hazard job function. Robots aren’t susceptible to “welder’s flash” or other common issues we run into with a human driven work force. However, there will still be instances where eliminating a hazard is not possible. For this reason, Safety Engineers around the globe have adopted the hierarchy of controls, which we will now discuss further.

The hierarchy of controls is a unique take on mitigating risk in the workplace. Typically, it is depicted as a “reverse-pyramid”, with the model portraying the top level as the most effective control measure, and the bottom being the least effective. As mentioned, sitting on top of the pyramid is elimination. Eliminating a hazard entirely will always be the best option. For risks that cannot be removed completely, we turn to substitution. Substitution focuses in on replacing a hazardous substance with a product that offers no, or less risk than the original item being used. An industry-relevant example that comes to mind is the use of oxygen-compatible “leak-check”. When filling oxygen, leak check must be sprayed on the cylinder valve to ensure no product is escaping the from the valve. Instead of removing this process, a product was substituted that contains no oil, grease or any similar ingredients that would be able to combine with oxygen to produce a flammable or explosive mixture. Is there still a risk? Sure. It can still be an irritant if it gets into your eyes, but this product is inherently less dangerous given the nature of its use.

The next two items commonly referred to in this model are Engineering and Administrative control measures. Engineering controls being more effective than Administrative. An engineering control is implemented with the goal of isolating the worker from the hazard that is present. A good example of this would be a wheel guard on a grinder. Grinding materials will produce sparks and debris that could come flying into the operator’s direction, potentially igniting their clothing or becoming trapped inside their eyes or ears. Grinding wheels are notorious for failing as well, which you’ve probably seen pictures of. They can shatter and shrapnel can fly towards the operator. Wheel guards do a great job at deflecting these sparks, debris and shrapnel from the user. Administrative controls focus on limiting one’s exposure to the recognized hazards. For example, a Dry Ice plant uses a modified wood-cutting machine to cut blocks that can be sold and shipped to customers. However, the machine being used produces noise over the recommended levels for an 8-hour shift. An administrative control would be to rotate workers working near the block maker to reduce their exposure. If you had a 4-person crew, 2 workers can operate the block maker for 4 hours and can then switch to the other essential job functions to limit any potential damage to their ears.

Now, as we’ve made our way down the pyramid of control measures, we’ve finally reached the bottom: PPE. Personal Protective Equipment is the least effective control measure in reference to this model. It acts as our “last line of defense” when performing our job duties. Although it is the least effective method for mitigating risk, it is still of the upmost importance to the safety and health of our work force. PPE is our fail-safe when other control measures have failed, it is a necessary redundancy factor that can be the difference between severe injury or even death. Safety glasses, ear plugs, respirators…whatever it may be, these tools were designed with one purpose in mind: protecting the worker. All these methods we have discussed are best utilized in conjunction with one another. Whether you are a safety professional, a line-worker, or a business owner, this model can and should be used to protect yourself and your co-workers alike. I hope this article has been beneficial to all readers. If this information is new to you, take a walk through your facility with these ideals in mind. Be creative and find new and improved ways to make 2020 the safest year on record.

"*" indicates required fields